Chain Drive Live Conveyors

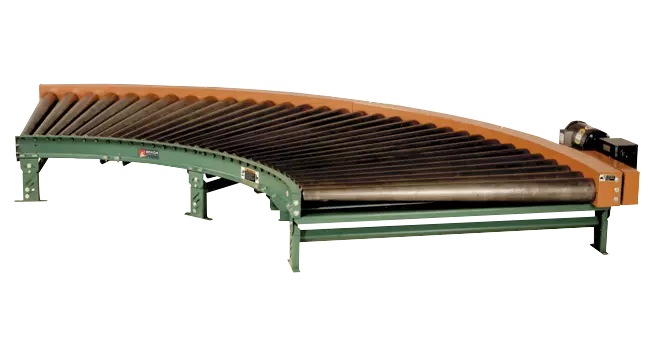

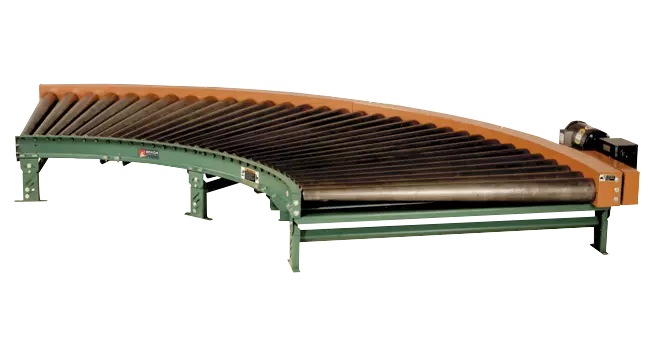

192 Chain Driven Medium Duty Live Roller Curve Conveyor

TREAD ROLLERS: 1.9″ dia. x 12 ga. steel, model 192S with sprockets.

CHAIN DRIVE: Roller to roller with No. 40 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor. ROLLER CENTERS: 5″ RC measured at outside radius of curve.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 40 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor. ROLLER CENTERS: 5″ RC measured at outside radius of curve.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

192 Chain Driven Medium Duty Roll to Roll Live Roller Conveyor

TREAD ROLLERS: 1.9″ dia. x 12 ga. steel, model 192S with sprockets.

CHAIN DRIVE: Roll-to-roll no. 40 roller chain.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 4″, 6″, 8″ or 12″ centers available.

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roll-to-roll no. 40 roller chain.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 4″, 6″, 8″ or 12″ centers available.

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

251 Chain Driven Heavy Duty Live Roller Conveyor

TREAD ROLLERS: 2-1/2″ dia. x 11 ga. steel rollers, model 251S with sprockets.

CHAIN DRIVE: Roll-to-roll no. 60 roller chain. ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

SPEED: 35 FPM, constant.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roll-to-roll no. 60 roller chain. ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

SPEED: 35 FPM, constant.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

251 Chain Driven Heavy Duty Live Roller Curve Conveyor

TREAD ROLLERS: 2-1/2″ dia. x 11 ga. steel, model 251S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty, ball bearings, zinc plated, grease packed, labyrinth sealed.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SPEED: 35 FPM, constant.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty, ball bearings, zinc plated, grease packed, labyrinth sealed.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SPEED: 35 FPM, constant.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

254 Chain Driven Medium Duty Tapered Roller Live Roller Curve Conveyor

TREAD ROLLERS: 2-1/2″ dia. to 1-11/16″ dia. x 14 ga. steel tapered rollers, model 254T with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive, side mounted or underside (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: Chain drive is enclosed, top and bottom, along entire length of conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

SPEED: 45 FPM, constant.

BEARINGS: Removable type, heavy duty bearings, zinc plated, grease packed, labyrinth sealed.

BED: 6″ x 1-1/2″ x 10 ga. and 4″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

297 Chain Driven Heavy Duty Live Roller Conveyor

TREAD ROLLERS: 2-9/16″ dia. x 7 ga. steel rollers, model 297S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame. Bed sections attached with couplings and floor supports.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame. Bed sections attached with couplings and floor supports.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

297 Chain Driven Heavy Duty Live Roller Curve Conveyor

TREAD ROLLERS: 2-9/16″ dia. x 7 ga. steel, model 297S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame.

BEARINGS: Removable type, heavy duty, ball bearings, zinc plated, grease packed, labyrinth sealed.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SPEED: 35 FPM, constant.

FLOOR SUPPORTS: SH-4 with underneath mounted drive adjustable 18″ to 21″ TOR. SH-1 with side mounted drive adjustable 10-1/2″ to 12″ TOR. Supports should be lagged to floor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

351 Chain Driven Medium Duty Tapered Roller Live Roller Curve Conveyor

TREAD ROLLERS: Heavy duty 11 ga. tapered rollers, model 351T with sprockets, for true taper effect.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive, side mounted or underside (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: Chain drive is enclosed, top and bottom, along entire length of conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty bearings, zinc plated, grease packed, labyrinth sealed.

BED: 5″ at 6.7 lbs. and 7″ at 9.8 lbs. structural steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive, side mounted or underside (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: Chain drive is enclosed, top and bottom, along entire length of conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty bearings, zinc plated, grease packed, labyrinth sealed.

BED: 5″ at 6.7 lbs. and 7″ at 9.8 lbs. structural steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

3530 Chain Driven Heavy Duty Live Roller Conveyor

TREAD ROLLERS: 3-1/2″ dia. x .300 wall steel, model 3530S with sprockets.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

BED LENGTHS (6″ RC, #60 CHAIN AND 12″ RC, #80 CHAIN): Intermediate bed section lengths 3′-0″, 4′-0″, 5′-0″, 6′-0″, 7′-0″, 8′-0″, 9′-0″ and 10′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

BED LENGTHS (7-1/2″ RC, #80 CHAIN): Intermediate bed section lengths 3′-1-1/2″, 3′-9″, 4′-4-1/2″, 5′-0″, 5′-7-1/2″, 6′-3″, 6′-10-1/2″, 7′-6″, 8′-1-1/2″, 8′-9″, 9′-4-1/2″ and 10′-0″. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

ROLLER CENTERS: 6″ with No. 60 chain; 7-1/2″ and 12″ with No. 80 chain.

CHAIN DRIVE: Roller to roller with No. 60 or No. 80 roller chain.

SPEED: 35 FPM, constant.

BED: 6″ at 8.2 lbs. and 8″ at 11.5 lbs. structural steel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ROLLER CAPACITY: 2500 lbs. per roller.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

BED LENGTHS (6″ RC, #60 CHAIN AND 12″ RC, #80 CHAIN): Intermediate bed section lengths 3′-0″, 4′-0″, 5′-0″, 6′-0″, 7′-0″, 8′-0″, 9′-0″ and 10′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

BED LENGTHS (7-1/2″ RC, #80 CHAIN): Intermediate bed section lengths 3′-1-1/2″, 3′-9″, 4′-4-1/2″, 5′-0″, 5′-7-1/2″, 6′-3″, 6′-10-1/2″, 7′-6″, 8′-1-1/2″, 8′-9″, 9′-4-1/2″ and 10′-0″. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

ROLLER CENTERS: 6″ with No. 60 chain; 7-1/2″ and 12″ with No. 80 chain.

CHAIN DRIVE: Roller to roller with No. 60 or No. 80 roller chain.

SPEED: 35 FPM, constant.

BED: 6″ at 8.2 lbs. and 8″ at 11.5 lbs. structural steel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ROLLER CAPACITY: 2500 lbs. per roller.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

192 Chain Driven Medium Duty Live Roller Curve Conveyor

TREAD ROLLERS: 1.9″ dia. x 12 ga. steel, model 192S with sprockets.

CHAIN DRIVE: Roller to roller with No. 40 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor. ROLLER CENTERS: 5″ RC measured at outside radius of curve.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

192 Chain Driven Medium Duty Roll to Roll Live Roller Conveyor

TREAD ROLLERS: 1.9″ dia. x 12 ga. steel, model 192S with sprockets.

CHAIN DRIVE: Roll-to-roll no. 40 roller chain.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 4″, 6″, 8″ or 12″ centers available.

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roll-to-roll no. 40 roller chain.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 4″, 6″, 8″ or 12″ centers available.

SPEED: 45 FPM, constant.

BEARINGS: Removable type, zinc-plated, grease packed, labyrinth sealed.

BED: 5-1/2″ x 1-1/2″ x 10 ga. and 3-1/2″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ELECTRICAL CONTROLS: Optional

251 Chain Driven Heavy Duty Live Roller Conveyor

TREAD ROLLERS: 2-1/2″ dia. x 11 ga. steel rollers, model 251S with sprockets.

CHAIN DRIVE: Roll-to-roll no. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

SPEED: 35 FPM, constant.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roll-to-roll no. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

SPEED: 35 FPM, constant.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

251 Chain Driven Heavy Duty Live Roller Curve Conveyor

TREAD ROLLERS: 2-1/2″ dia. x 11 ga. steel, model 251S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty, ball bearings, zinc plated, grease packed, labyrinth sealed.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SPEED: 35 FPM, constant.

BED: 6″ x 1-1/2″ x 7 ga. and 4″ x 1-1/2″ x 7 ga. formed steel channel frame.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

254 Chain Driven Medium Duty Tapered Roller Live Roller Curve Conveyor

TREAD ROLLERS: 2-1/2″ dia. to 1-11/16″ dia. x 14 ga. steel tapered rollers, model 254T with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive, side mounted or underside (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: Chain drive is enclosed, top and bottom, along entire length of conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

SPEED: 45 FPM, constant.

BEARINGS: Removable type, heavy duty bearings, zinc plated, grease packed, labyrinth sealed.

BED: 6″ x 1-1/2″ x 10 ga. and 4″ x 1-1/2″ x 10 ga. formed steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

297 Chain Driven Heavy Duty Live Roller Conveyor

TREAD ROLLERS: 2-9/16″ dia. x 7 ga. steel rollers, model 297S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame. Bed sections attached with couplings and floor supports.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor. BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame. Bed sections attached with couplings and floor supports.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor. BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

297 Chain Driven Heavy Duty Live Roller Curve Conveyor

TREAD ROLLERS: 2-9/16″ dia. x 7 ga. steel, model 297S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame.

BEARINGS: Removable type, heavy duty, ball bearings, zinc plated, grease packed, labyrinth sealed.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SPEED: 35 FPM, constant.

FLOOR SUPPORTS: SH-4 with underneath mounted drive adjustable 18″ to 21″ TOR. SH-1 with side mounted drive adjustable 10-1/2″ to 12″ TOR. Supports should be lagged to floor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame.

BEARINGS: Removable type, heavy duty, ball bearings, zinc plated, grease packed, labyrinth sealed.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SPEED: 35 FPM, constant.

FLOOR SUPPORTS: SH-4 with underneath mounted drive adjustable 18″ to 21″ TOR. SH-1 with side mounted drive adjustable 10-1/2″ to 12″ TOR. Supports should be lagged to floor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

351 Chain Driven Medium Duty Tapered Roller Live Roller Curve Conveyor

TREAD ROLLERS: Heavy duty 11 ga. tapered rollers, model 351T with sprockets, for true taper effect.

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive, side mounted or underside (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: Chain drive is enclosed, top and bottom, along entire length of conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty bearings, zinc plated, grease packed, labyrinth sealed.

BED: 5″ at 6.7 lbs. and 7″ at 9.8 lbs. structural steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

CHAIN DRIVE: Roller to roller with No. 60 circular roller chain.

END DRIVE: Reversible drive, side mounted or underside (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

CHAIN GUARD: Chain drive is enclosed, top and bottom, along entire length of conveyor.

ROLLER CENTERS: 6″ RC measured at outside radius of curve.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty bearings, zinc plated, grease packed, labyrinth sealed.

BED: 5″ at 6.7 lbs. and 7″ at 9.8 lbs. structural steel channel frame.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

DRIVE LOCATION: Drive located on outside of curve. Specify right hand drive or left hand drive (drive hand determined with reference point located at outside of curve).

ELECTRICAL CONTROLS: Optional

3530 Chain Driven Heavy Duty Live Roller Conveyor

TREAD ROLLERS: 3-1/2″ dia. x .300 wall steel, model 3530S with sprockets.

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum). BED LENGTHS (6″ RC, #60 CHAIN AND 12″ RC, #80 CHAIN): Intermediate bed section lengths 3′-0″, 4′-0″, 5′-0″, 6′-0″, 7′-0″, 8′-0″, 9′-0″ and 10′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

BED LENGTHS (7-1/2″ RC, #80 CHAIN): Intermediate bed section lengths 3′-1-1/2″, 3′-9″, 4′-4-1/2″, 5′-0″, 5′-7-1/2″, 6′-3″, 6′-10-1/2″, 7′-6″, 8′-1-1/2″, 8′-9″, 9′-4-1/2″ and 10′-0″. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

ROLLER CENTERS: 6″ with No. 60 chain; 7-1/2″ and 12″ with No. 80 chain.

CHAIN DRIVE: Roller to roller with No. 60 or No. 80 roller chain.

SPEED: 35 FPM, constant.

BED: 6″ at 8.2 lbs. and 8″ at 11.5 lbs. structural steel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ROLLER CAPACITY: 2500 lbs. per roller.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum). BED LENGTHS (6″ RC, #60 CHAIN AND 12″ RC, #80 CHAIN): Intermediate bed section lengths 3′-0″, 4′-0″, 5′-0″, 6′-0″, 7′-0″, 8′-0″, 9′-0″ and 10′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

BED LENGTHS (7-1/2″ RC, #80 CHAIN): Intermediate bed section lengths 3′-1-1/2″, 3′-9″, 4′-4-1/2″, 5′-0″, 5′-7-1/2″, 6′-3″, 6′-10-1/2″, 7′-6″, 8′-1-1/2″, 8′-9″, 9′-4-1/2″ and 10′-0″. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

ROLLER CENTERS: 6″ with No. 60 chain; 7-1/2″ and 12″ with No. 80 chain.

CHAIN DRIVE: Roller to roller with No. 60 or No. 80 roller chain.

SPEED: 35 FPM, constant.

BED: 6″ at 8.2 lbs. and 8″ at 11.5 lbs. structural steel frame. Bed sections attached with couplings and floor supports.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ROLLER CAPACITY: 2500 lbs. per roller.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional